Elevating Cooling Tower Performance: Superior Water Treatment Systems Explained

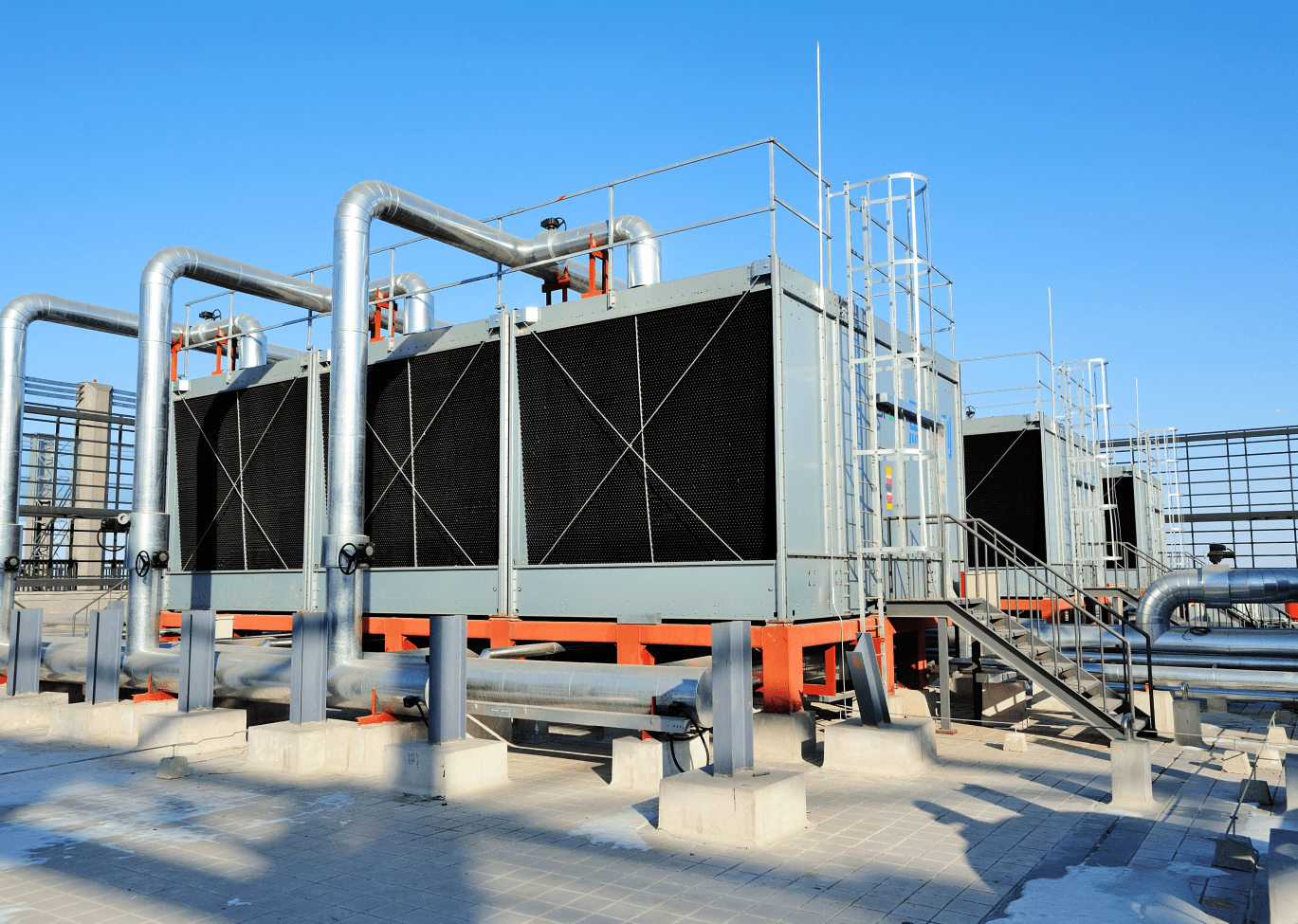

Cooling towers are the backbone of many industrial and commercial HVAC operations, efficiently handling heat rejection. Yet the recirculating water inside these towers inevitably accumulates impurities, which can lead to scale, corrosion, microbial growth, and other operational challenges. As a water treater, your role is to safeguard water quality and maximize cooling tower performance through strategic, well-maintained water treatment systems. Below, we explore the various treatment options, factors influencing system selection, and the benefits they provide for both equipment and the environment.

Why Cooling Tower Water Treatment Matters

Without proper water treatment, contaminants can quickly degrade a cooling tower’s efficiency and reliability. Scale build-up and corrosion reduce heat transfer and drive up energy costs, while microbial growth can pose health risks and lead to unscheduled downtime. Effective water treatment tackles these issues proactively, ensuring your cooling tower stays resilient, efficient, and compliant with environmental standards.

Key Types of Cooling Tower Water Treatment Systems

-

Filtration Systems

- Purpose: Remove suspended solids such as dirt, rust, and algae.

- Methods: Sand filters, cartridge filters, precoat filters.

- Benefits: Clean, debris-free water reduces fouling and maximizes heat exchange efficiency.

-

Side-Stream Filtration

- Purpose: Treat only a portion of the recirculating water, continuously removing impurities that accumulate over time.

- Benefits: Maintains overall water quality, lowers chemical usage, and prevents heavy contaminant load in the main system.

-

Ion Exchange & Water Softening

- Purpose: Eliminate dissolved salts—particularly calcium and magnesium—that cause scale.

- Benefits: Prevents mineral deposits on heat transfer surfaces, reducing energy consumption and extending equipment life.

-

Chemical Treatment Systems

- Purpose: Control scale, corrosion, and microbial activity via specialized chemicals (inhibitors, biocides, algaecides).

- Benefits: Mitigates damage to metal surfaces, lowers the risk of costly repairs, and preserves system longevity.

-

Ultrafiltration Systems

- Purpose: Employ semipermeable membranes to remove suspended solids, colloids, and dissolved macromolecules.

- Benefits: Produces high-quality water with minimal chemical reliance—ideal for facilities aiming to minimize environmental impact.

Selecting the Right System

- Contaminant Profile: Analyze water quality to identify specific contaminants—such as hardness minerals, organic matter, or microbial content.

- Cooling Tower Size & Design: Larger or high-capacity towers may require more robust systems like side-stream filtration or ultrafiltration.

- Regulatory & Environmental Factors: Comply with local or national water discharge and chemical use regulations. Systems with lower chemical consumption may be beneficial in highly regulated regions.

- Cost & Efficiency: Balance upfront investment against long-term operational savings. A more advanced system often pays off via reduced energy costs and extended equipment life.

- Expert Consultation: Water treatment specialists can provide tailored advice based on unique site conditions and production demands.

Benefits of Effective Cooling Tower Water Treatment

- Enhanced Heat Transfer Efficiency: Clean surfaces transfer heat more effectively, curbing energy consumption.

- Extended Equipment Life: By preventing corrosion and erosion, you reduce maintenance expenses and system downtime.

- Reliable Operations: Fewer impurities mean fewer malfunctions, ensuring consistent cooling performance.

- Environmental Compliance: Lower contaminant levels and responsible chemical usage help meet or exceed regulatory requirements.

The Role of the Water Treater

Continuous Monitoring and Proactive Maintenance are critical to staying ahead of water quality issues. Regular sampling, data analysis, and system checks help detect early signs of scaling or biofouling, enabling timely interventions. As a water treater, you’re also responsible for guiding facility staff on proper usage, maintenance, and adherence to environmental standards.

Embracing Innovation:

- IoT Sensors & Analytics: Real-time tracking of temperature, pH levels, and other metrics gives immediate insight into system health.

- Automated Alerts: Early detection of off-standard readings allows swift corrective action.

Training and Preparedness

Well-trained operators understand how to run and maintain water treatment systems effectively, ensuring minimal downtime and maximum reliability. Regular training sessions on system operation, regulatory compliance, and emergency responses can significantly improve overall efficiency.

Superior water treatment systems are the linchpin of high-performing cooling towers. By choosing the right mix of filtration methods, chemical treatments, and advanced technologies, you reduce operational risks, extend equipment lifespan, and uphold environmental stewardship. As a water treater, you hold the keys to ensuring optimized cooling tower performance—striking the perfect balance between cost, compliance, and sustainable operations.

Related Articles

Sign Up to Receive Water Facts Emails

Learn more about our Water Treatment Services and Chemical Products

Contact Us