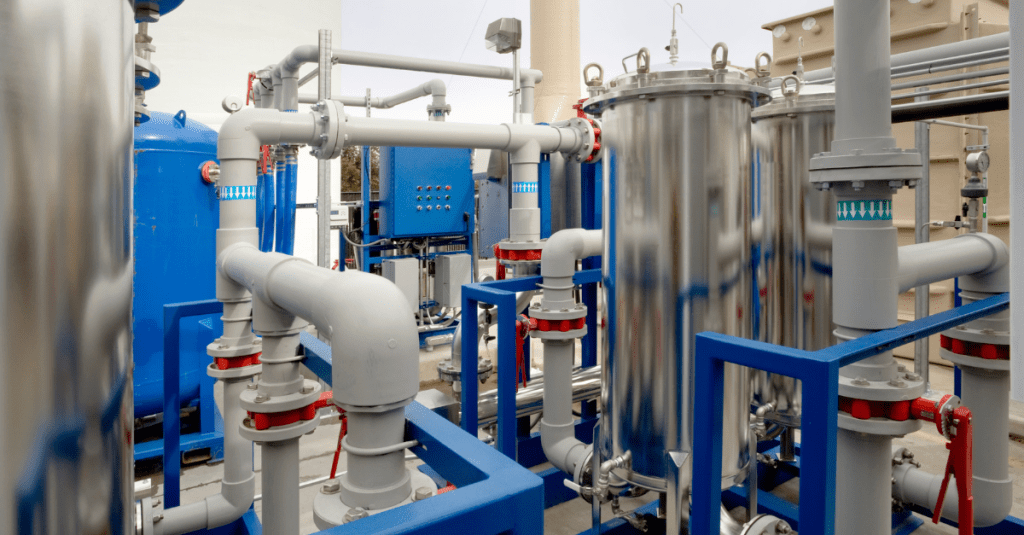

Electro Deionizer (EDI) is an essential component in water treatment systems, ensuring the delivery of high-purity water for various industrial applications. ST108 equipment stands out in this domain, offering reliability and efficiency. This article delves into the workings, benefits, and applications of EDI systems, with a focus on ST108 equipment.

An electro deionizer is a water purification process that combines ion exchange resins and electricity to remove ionized species from water. Unlike traditional deionization methods, an electro deionizer does not require chemical regeneration, making it a more sustainable and cost-effective solution.

An electro deionizer uses a combination of ion exchange resins and electrically active membranes to separate and remove ions from water. The process begins with pre-treatment, where water is filtered to remove larger contaminants and particulates. Following this, the water passes through ion exchange resins that attract and bind ions. An electric current is then applied, driving the ions through the membranes and out of the water stream. Finally, the purified water undergoes a polishing step to ensure high purity.

ST108 electro deionizers offer several advantages. They ensure consistent water quality with minimal downtime, making them highly efficient. The reduced need for chemical regenerants lowers operational costs, contributing to their cost-effectiveness. Additionally, the process minimizes waste and chemical use, supporting sustainability initiatives. The robust design of ST108 equipment ensures long-term, trouble-free operation, making them reliable for various applications.

Electro deionizers are utilized in several industries where high-purity water is crucial. In the pharmaceutical industry, an electro deionizer is used for producing injectable solutions and other sterile products. The electronics industry relies on electro deionizers for semiconductor manufacturing and other production processes. In power generation, high-purity water is essential for boiler feedwater and other critical applications. The food and beverage industry also uses electro deionizers to ensure water purity for production processes and product quality.

To maintain optimal performance of ST108 electro deionizers, regular monitoring of water quality parameters and system performance is essential. Following a maintenance schedule helps prevent unexpected downtime. Proper pre-treatment of the water is crucial to extend the lifespan of the electro deionizer. Additionally, it is important to equip your team with the necessary training to handle and troubleshoot the equipment effectively.

Electro deionizers, particularly those in the ST108 range, offer a reliable, efficient, and sustainable solution for high-purity water needs. By understanding the workings and benefits of these systems, industries can ensure optimal water quality and operational efficiency. Whether for pharmaceuticals, electronics, power generation, or food and beverage, ST108 electro deionizers are a valuable asset in any water treatment arsenal.

The lifespan of an electro deionizer can vary depending on the quality of maintenance and the specific application. Generally, they can last several years with proper care and regular maintenance.

Regular servicing of an electro deionizer is recommended every 6 to 12 months, depending on the usage and water quality. This helps ensure optimal performance and longevity.

Electro deionizers are highly effective at removing ionic contaminants but may not remove all types of contaminants. Pre-treatment processes are essential to address non-ionic impurities.

Yes, electro deionizers are environmentally friendly as they minimize the use of chemicals and reduce waste production compared to traditional deionization methods.