The Matec Acquae Filter Presses are meticulously designed to offer compact and functional solutions optimized for small to medium industries. This model incorporates advanced specifications adapted from Matec’s larger machines, making it versatile for a range of applications.

Named after the Latin word “Acquae,” meaning “water,” the Acquae Filter Press is engineered to maximize water recovery, especially at minimal flow rates, reinforcing water’s role as a valuable resource. This model range includes various sizes—400×400, 500×500, and 630×630—offering adaptable capacity options to meet industry-specific requirements.

The Matec Acquae Filter Press range is ideal for recycling water, minimizing waste, and cutting operational costs across industrial applications such as marble, ceramic, and cement processing. For industries focused on sustainable and efficient water management, these filter presses deliver robust solutions that align with environmental and cost-saving goals.

What industries benefit from the Matec Acquae Filter Press?

The Matec Acquae Filter Press is highly versatile and benefits industries such as marble and granite processing, ceramics, cement, high-tech mining, and aggregates recycling. It is designed to manage diverse flow rates across these sectors, supporting efficient water recovery.

What is the purpose of the Batch Water Recovery (BWR) system in the Matec Acquae Filter Press?

The BWR system is specifically designed to recycle water from cement mixers in the cement sector. This feature helps in reusing water, reducing waste, and ensuring efficient resource management.

How does the High-Pressure Technology (HPT) enhance the Matec Acquae Filter Press performance?

The HPT allows the filter press to operate at over 20 BAR, enabling effective dewatering and solid-liquid separation. This high-pressure capability ensures that industries achieve the required solid content and water clarity efficiently.

What maintenance features does the Matec Acquae Filter Press offer?

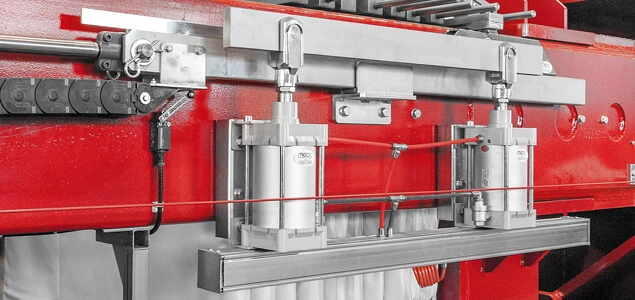

The Matec Acquae Filter Press includes features such as Gasser Shakers for optimal cake discharge, an automated washing system for thorough cleaning, and a user-friendly filter cloth design that allows for easy replacement, minimizing downtime and enhancing operational efficiency.

Is the Matec Acquae Filter Press customizable for different capacity needs?

Yes, the Matec Acquae Filter Press offers several model sizes (400×400, 500×500, and 630×630) and accommodates up to 50 plates, allowing flexibility to meet specific capacity requirements across various applications.