All closed-loop water systems are susceptible to corrosion to metal piping and components, even with chemical treatment. The most common type of corrosion is magnetite. Magnetite is a magnetic particle generated through deprivation from oxygen in a closed loop system where iron is present – essentially a corrosion byproduct creating iron oxide. As water is introduced to a closed system and over time the oxygen is deprived, the iron pipes will form a magnetite layer on the inner surface of the clean pipes. This layer is typically black in nature and provides a protective barrier when formed. Over time, however, with oxygen absorption these magnetite particles, which are very fine, sub 5 um, will get into the water stream and circulate around. They are smaller than a normal bag filter can capture and easily deposit in various dead legs of the water system.

When operating in exceptionally challenging conditions, even the best-designed heat exchangers will be susceptible to fouling from corrosion byproducts, scale, and insoluble materials. The heat exchange surface in a water system is one of the most important and valuable components of your water circuit – the smallest amount of fouling, even 1/100th of an inch, can reduce the efficiency of the system by 10% – that’s a huge saving when we can prevent it. The MagStrainer solves this problem through sidestream or inline magnetic water filtration systems.

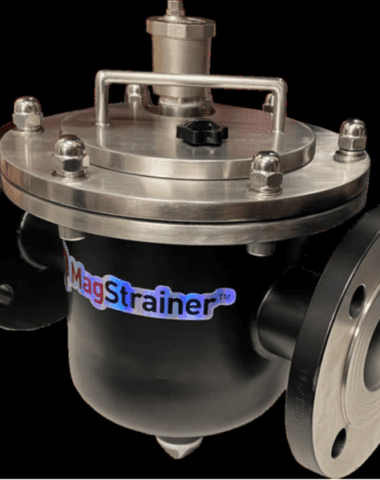

Request InfoThe MagStrainer™ H1s are housed in stainless steel filter housings of various sizes. Each unit contains the longest powerful magnet assembly available today, a bag filter, and the unit can serve as a pot feeder for chemical dosing applications for hydronic systems.

The MagStrainer™ H2 is designed for large and small commercial and industrial systems and removes nearly 100% of magnetite and other unwanted debris from hydronic systems.

| Product | Application Use | Description |

|---|---|---|

| MagStrainer™ H1 Series | The MagStrainer ™ H1 series is set to revolutionize magnetic filtration. The H1 can work with virtually any size pipe, making it ideal for smaller commercial systems to the largest of industrial systems for factories, hospitals, and other building complexes. The H1 is designed to work as a full flow or inline component or as a sidestream filter depending on the need and application. The H1 removes nearly 100% of magnetite and other unwanted debris from hydronic systems. The filter uses long Neodymium high intensity magnetic rods, capturing visible and sub-micronic magnetite (iron oxide) and other non-magnetic contaminants and collects them in the filter. |

The MagStrainer™ H1 line uniquely combines three key filtration elements in one unit: a powerful magnet set, a bag filter for larger particulate matter, and a chemical pot feeder for dosing and system maintenance. Available in sizes from 1″ NPT, and 2″-8″ Flange connections. |

| MagStrainer™ H2 Series | Designed to be an inline filter, the H2 gets installed on the return circuit close to the boiler as the system water flows back. The H2 captures visible and microscopic magnetite (iron oxide) collects them in the filter. The MagStrainer H2 filter captures existing contamination, prevents further buildup, increases system efficiency thus lowering costs, protects boilers and ECM heat pumps, prevents “cold spots” in the systems, extends the long term life of these systems, and reduces maintenance overall. |

The MagStrainer™ H2 is designed for large and small commercial and industrial systems and removes nearly 100% of magnetite and other unwanted debris from hydronic systems. Available in sizes 2″, 3″, 4″, 6″, 8″, 10″ and 12″ flange connections. |