Reverse osmosis (RO) is an advanced water purification process that is extensively used in both industrial and residential settings. This technology is vital for ensuring access to clean and safe water by efficiently removing contaminants and impurities. In this guide, we explore the principles of reverse osmosis, its numerous benefits, and its various applications.

Is is a water purification method that utilizes a semipermeable membrane to filter out ions, molecules, and larger particles from water. During the RO process, water is pushed through the membrane under pressure, leaving contaminants behind and allowing only purified water to pass through. This method effectively removes a wide range of impurities, including salts, bacteria, and harmful chemicals.

1,800 – 7,200 Gallons Per Day, compact system for small-scale applications., an affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint make this the perfect system for your application.

5,000 – 10,000 Gallons Per Day, high-efficiency system for medium-scale needs. An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

144,000 Gallons Per Day, advanced system for maximum water purity. An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

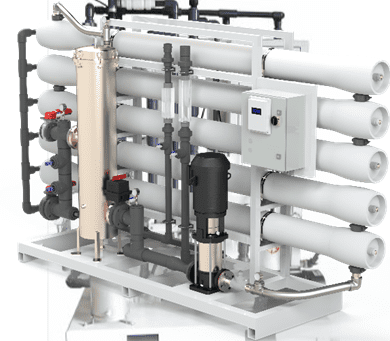

23,080 – 46,000 Gallons Per Day, industrial-grade system for large-scale operations, An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

69,000 – 172,500 Gallons Per Day, robust system for extensive industrial use. An affordable line of RO systems designed with the end user in mind. All the features you need in a small footprint makes this the perfect system for your application.

The reverse osmosis process consists of several key stages:

RO systems provide several significant advantages:

RO technology is employed across multiple sectors:

To ensure optimal performance, regular maintenance of RO systems is essential:

RO is a powerful and versatile water purification technology that ensures the availability of clean and safe water for various applications. Whether for residential, commercial, or industrial use, these systems provide effective contaminant removal, improving water quality and safety. Understanding the principles, benefits, and maintenance can help in choosing and maintaining the right system for your needs.

The membrane typically needs replacement every 2-3 years, depending on water quality and usage.

Yes, RO water is safe to drink and often tastes better than untreated water due to the removal of impurities.

It removes a wide range of contaminants, including heavy metals, salts, chlorine, bacteria, and viruses.

While these systems do produce some reject water, modern designs minimize waste and improve efficiency.