How Industrial Wastewater Pretreatment Works

What is Pretreatment?

Industrial wastewater pretreatment is the removal of harmful contaminants before discharging water into municipal sewer systems or reusing it in plant operations. Proper pretreatment is essential for:

- Meeting discharge regulations

- Avoiding fines and legal action

- Ensuring product quality

- Reducing wastewater surcharge costs

At ChemREADY, we specialize in industrial effluent treatment solutions, customizing pretreatment processes to help facilities cut costs, stay compliant, and improve water reuse efficiency.

🔹 Explore Our Wastewater Treatment Solutions

The Industrial Wastewater Treatment Process

The pretreatment process starts with analyzing wastewater composition and determining discharge requirements. The primary goal is to remove waste solids, including:

- Suspended solids

- Dissolved solids

- Metals

- Synthetic chemicals

This is achieved through chemical treatments and mechanical filtration methods.

What Chemicals Are Used in Wastewater Pretreatment?

Industrial wastewater pretreatment relies on chemical processes to remove dissolved contaminants and enhance solid separation. The three primary types of chemical treatment include:

1. pH Adjusters

pH control is crucial for wastewater pretreatment, especially for removing metal ions and dissolved chemicals. Common pH adjusters include:

- Lime slurry (calcium hydroxide)

- Caustic soda (sodium hydroxide)

- Soda ash (sodium carbonate)

These chemicals help precipitate metals into solid particles that can be filtered out.

🔹 Learn More About pH & Alkalinity Adjusters

2. Coagulants

Coagulants neutralize charged particles, allowing suspended solids to aggregate into a manageable form. These fall into two categories:

- Inorganic coagulants (e.g., aluminum sulfate, ferric sulfate) – Cost-effective but increase sludge volume.

- Organic coagulants (e.g., polyamines, polyDADMACs) – Require lower dosages and create less sludge.

3. Flocculants

Flocculants help clump contaminants into larger particles that float or settle, making filtration easier. These include:

- Natural flocculants (e.g., activated silica, polysaccharides)

- Synthetic flocculants (e.g., polyacrylamide-based formulations)

ChemREADY’s FlocREADY line offers a wide range of flocculants and coagulants tailored to your specific needs.

🔹 Discover FlocREADY Coagulants & Flocculants

Mechanical Filtration & Dewatering Methods

After chemical pretreatment, wastewater undergoes filtration to remove solid contaminants. The most common filtration systems include:

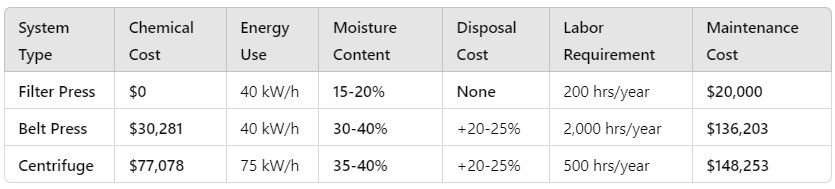

1. Centrifuges

- Use rapid spinning to separate solids from liquids.

- High operational cost due to energy use and chemical consumption.

- Best for high-density sludges but not cost-effective for most industries.

2. Belt Presses

- Continuous dewatering process using gravity and mechanical pressure.

- Requires additional flocculants and has higher operational costs.

- Ideal for municipal wastewater plants.

3. Filter Presses (Best for Industrial Use)

- Uses high-pressure filtration to create dry filter cakes.

- Fully automated systems reduce labor costs.

- Lowest operating cost compared to centrifuges and belt presses.

- Ideal for mining, aggregates, concrete, and industrial wastewater treatment.

Table 1: Filtration Operating Costs & Resource Requirements

🔹 Explore Our Filter Press Solutions

Choosing the Right Wastewater Pretreatment Method

Selecting the best pretreatment method depends on your industry, wastewater composition, and compliance needs.

For industrial wastewater treatment:

- Filter presses offer low-cost, high-efficiency dewatering.

- Belt presses are suited for municipal wastewater.

- Centrifuges are ideal for high-density sludges but costly.

At ChemREADY, we offer customized solutions for every industry and wastewater type.

🔹 Schedule a Consultation with Our Experts

The ChemREADY Advantage

ChemREADY provides comprehensive wastewater treatment solutions for industrial and municipal applications. Our services include:

- Customized chemical treatment programs

- Pretreatment system design & optimization

- Industrial wastewater compliance consulting

- Total Service Management & on-site support

🔹 Learn More About ChemREADY’s Wastewater Treatment Services

FAQs About Industrial Wastewater Pretreatment

1. What is industrial wastewater pretreatment?

Pretreatment removes harmful contaminants from industrial wastewater before discharge or reuse, ensuring compliance with EPA and local regulations.

2. What chemicals are used in wastewater pretreatment?

Common pretreatment chemicals include pH adjusters, coagulants, and flocculants, which help remove suspended solids, metals, and dissolved chemicals.

3. What is the best filtration method for industrial wastewater?

For most industries, filter presses offer the lowest operating cost and highest dewatering efficiency compared to belt presses and centrifuges.

4. How can ChemREADY help with wastewater pretreatment?

We provide custom treatment plans, chemical solutions, filtration systems, and compliance consulting to help you reduce costs and stay compliant.