In the ST108 Implementation Timeline, Step 5 focuses on selecting and installing ST108 water treatment systems. This step is essential for ensuring that your facility’s water quality meets the needs of medical device processing.

Before selecting a water treatment system, it’s crucial to evaluate your facility’s specific water quality requirements. Consider the types of medical devices you process and the water quality needed at each stage—from pre-cleaning to final rinsing and sterilization. Tailoring the system to these needs ensures optimal safety and efficiency.

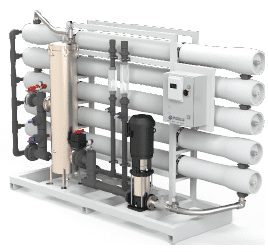

Achieving high water quality often requires integrating multiple water treatment methods into a cohesive system. Combining methods such as softening, filtration, reverse osmosis, and deionization ensures that contaminants are removed at different stages. Proper system integration, guided by water treatment experts, not only enhances performance but also supports easy maintenance and consistent water quality monitoring.

A typical system designed to meet ST108 standards for ST108 water treatment systems includes the following components:

Once treated, water should be stored in specially designed tanks to prevent contamination and microbial growth. Proper storage maintains water quality until it’s needed for medical device processing. The Loop Boss is a standout distribution system that ensures water remains contaminant-free right up to the point of use. Featuring 0.2-micron filters, UV disinfection, and built-in monitoring technology, the Loop Boss is designed for easy maintenance and optimized performance.

Selecting the right water treatment systems is about balancing cost and efficiency. When evaluating different options, prioritize systems that offer a reliable return on investment through better water quality, reduced downtime, and long-term savings. Consulting with water treatment experts ensures that the system selected meets both operational needs and budget constraints.

Choosing and installing the appropriate water treatment system is a foundational step for maintaining safe and effective water quality in medical device processing. By assessing your water quality needs, integrating various treatment methods, and consulting with professionals, you can ensure that your facility meets ST108 compliance standards for ST108 water treatment systems. For more information and assistance with your ST108 compliance, visit our page on ST108 Testing.

Ben Frieders is the Business Development and Marketing Manager at ChemREADY, an industrial water treatment company, where he focuses on driving growth through strategic marketing, business development, and acquisitions. A former U.S. Navy Chief Petty Officer with a background in nuclear operations, Ben brings a unique blend of technical expertise and leadership to the water treatment industry. Certified in ASSE 12080 Legionella Water Safety and Management, he is a recognized expert in water quality standards, regulatory compliance, and Legionella risk management. Passionate about scaling businesses and optimizing systems, Ben combines data-driven strategies with a hands-on approach to help organizations achieve sustainable growth.