ORP stands for oxidation-reduction potential. It is a measure of the tendency of a substance to either gain or lose electrons in a chemical reaction. ORP is typically measured in millivolts (mV) and is often used as an indicator of water quality. In the context of water treatment, ORP is used to determine the effectiveness of disinfection processes. ORP values can also be used to monitor and control the levels of disinfectants such as chlorine or ozone in water systems. In general, a higher ORP indicates a greater potential for oxidation, while a lower ORP indicates a greater potential for reduction. ORP values can be affected by factors such as pH, temperature, and the presence of other substances in the water.

ORP provides several values that can be useful in different contexts. Some of these values are:

Overall, ORP is a versatile parameter that can provide valuable information on water quality, disinfection efficacy, corrosion potential, and process control.

Monitoring ORP in a cooling tower is important for several reasons.

Overall, monitoring ORP in a cooling tower can help ensure that the tower is operating efficiently and safely, while also reducing the risk of equipment damage and microbial growth.

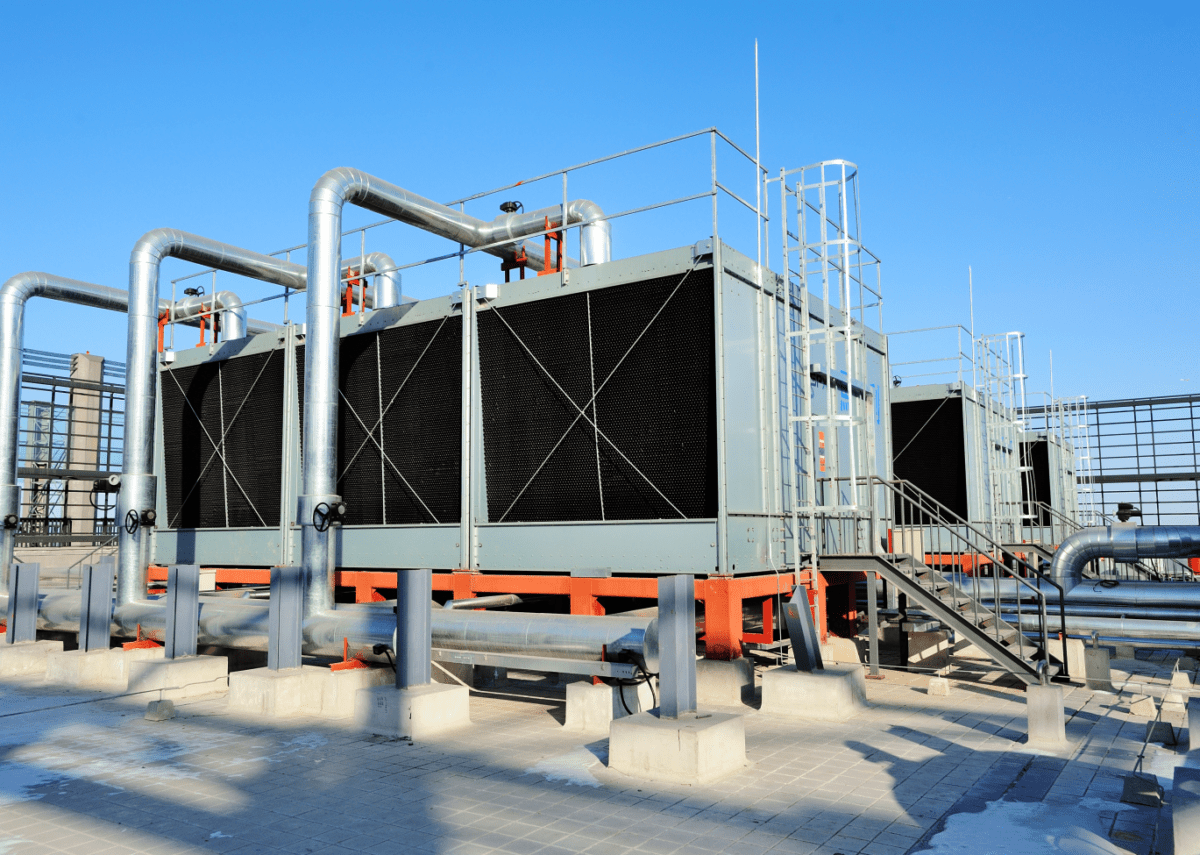

ORP values can be measured using a variety of instruments, including handheld ORP meters or inline probes that continuously monitor ORP levels. In general, ORP values in cooling towers should be maintained in the range of 650 to 750 mV, which is considered optimal for controlling microbial growth and minimizing corrosion. However, the optimal ORP range can vary depending on factors such as water chemistry, temperature, and the type of cooling tower system.

When interpreting ORP values in cooling towers, it is essential to consider the context in which they were measured. ORP values can fluctuate depending on factors such as pH, temperature, and the presence of other substances in the water. For example, high levels of dissolved solids or organic matter can reduce ORP values even in the presence of adequate disinfection measures. Therefore, it is important to measure ORP values in conjunction with other water quality parameters such as pH, conductivity, and total dissolved solids.

To maintain optimal ORP levels in cooling towers, it is essential to implement best practices for water treatment and management. Here are some best practices that can help maintain optimal ORP levels in cooling towers:

ORP monitoring is a critical component of cooling tower management, helping to ensure that the tower operates efficiently and safely while minimizing the risk of equipment damage and microbial growth. ORP values can fluctuate depending on a variety of factors, including water chemistry, temperature, and the presence of other substances in the water. Therefore, it is essential to measure ORP values in conjunction with other water quality parameters and to implement best practices for water treatment and management. By taking a proactive approach to oxidation-reduction potential monitoring and maintenance, organizations can maximize the performance and lifespan of their cooling tower systems.

Nick Piskura is the Marketing and Web Development Specialist at ChemREADY who utilizes expertise in digital marketing strategies to provide knowledgeable insights in each segment of our business. Nick provides insights through web development and multimedia resources that support ChemREADY’s full range of services, including Legionella management, ANSI/AAMI ST108 compliance, boiler and cooling tower treatment, wastewater processing, and industrial water quality solutions.