Reading Time | 5 Minutes

High-efficiency side-stream filtration keeps cooling towers clean, stable, and efficient. By skimming a portion of circulating water and stripping out fine and ultra-fine particles, you cut the root cause of many tower headaches: fouling, poor heat transfer, weak biocide performance, and rising energy spend.

A clean tower runs cooler and lasts longer. Side-stream filtration bolts onto the loop and runs continuously during normal operation, treating a slipstream rather than the full flow. This constant polish removes suspended solids, organics, and silt so plant teams can keep scale, corrosion, and biofilm under control. You get fewer blowdowns, steadier temperatures, and less labour on heat-exchange surfaces. Units are non-destructive, modular, and can be added or removed without shutting the tower, which keeps production on track.

The smallest particles cause the biggest trouble. In towers, recirculation concentrates debris from air and make-up water. Most contaminants sit in the 0.5–2 micron band, which passes straight through coarse filters. Those fines seed biofilm, trigger under-deposit corrosion, and blunt biocides and inhibitors. Problems stack up: more fouling → more corrosion → more scale → worse heat transfer.

Most tower problems start with ultra-fine solids that standard filtration misses. A particle analysis can confirm what’s in your loop and whether side-stream filtration will deliver measurable improvements.

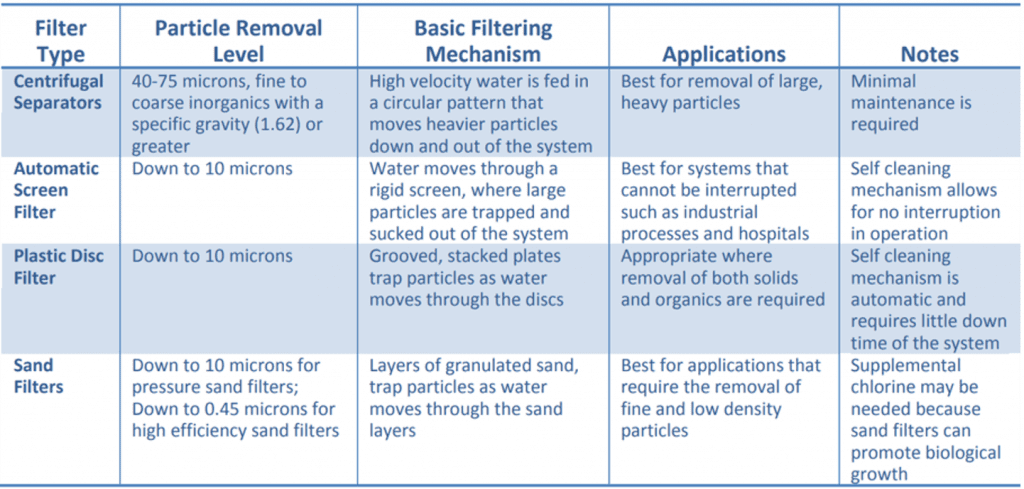

Bag and cartridge filters load up fast in wet duty and become expensive to keep online. High-efficiency sand filters use graded media to trap ultra-fine particles as water moves through the bed.

Many common filters: often 10 microns at best. That gap matters because particles left in the 0.5–5 micron range include bacteria and biofilm builders that undermine the rest of your treatment programme.

Tip: run a particle analysis first so your spec matches the contaminants actually present.

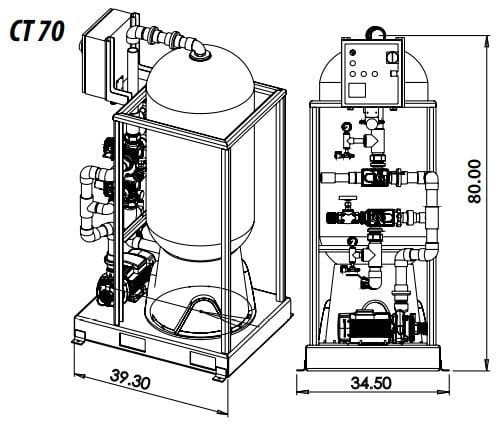

ChemREADY’s high-efficiency system filters are built for continuous tower duty with a compact footprint and quick set-up.

Pair filtration with a smart chemical plan — oxidising/non-oxidising biocides, dispersants, and corrosion/scale inhibitors — and you’ll keep the loop clean over the long haul.

Flow rate, micron rating, and footprint all matter. ChemREADY helps match high-efficiency side-stream filters to your tower size, contaminant profile, and operating constraints.

Clarify the risks: Confirm particle size distribution, suspended solids, and biological activity. Check makeup quality and cycles of concentration.

Select the filter: Match media and flow to the contaminant profile and target micron rating. Account for available pad space, hydraulics, and service access.

Integrate with chemistry: Keep pH in the target band for your metallurgy. Alternate biocides, use dispersants to move dead biomass, and trend dip-slide or ATP results.

Operate and trend: Log differential pressure, flow, and particle counts. Review data with dose, temperature, and weather so adjustments stick.

Quick spec checklist

Side stream filters remove suspended solids, silt, organic material, and ultra-fine particulate from recirculating cooling tower water. High-efficiency models can remove particles as small as 0.45 microns, which are often responsible for fouling, corrosion, and biofilm growth.

Side stream filtration treats only a portion of the system water at a time—typically 5–15%—continuously during operation. In contrast, full-flow filtration treats all the circulating water, which often requires more complex infrastructure and higher operating costs.

Ultra-fine particulate (0.5–2 microns) accumulates over time in cooling tower systems and can:

No. Most high-efficiency side stream filtration units, like ChemREADY’s modular systems, are designed for crane-free installation and operate independently without requiring system shutdowns or interruptions.

Particle analysis should be conducted regularly—ideally quarterly or bi-annually—to ensure your filtration system is removing contaminants effectively. Testing helps determine if adjustments or upgrades are needed.

While chemical treatment (like biocides and scale inhibitors) is essential, it’s not enough on its own. Without filtration, fine particulates can still accumulate, reducing chemical efficiency and requiring more frequent mechanical cleaning.

You should first perform a particle analysis to understand your water’s specific contaminant profile. This data will help you select a filter with the appropriate micron rating and flow capacity for your system size and operational goals.