What Type Of Equipment Do I Need For My Cooling Tower System?

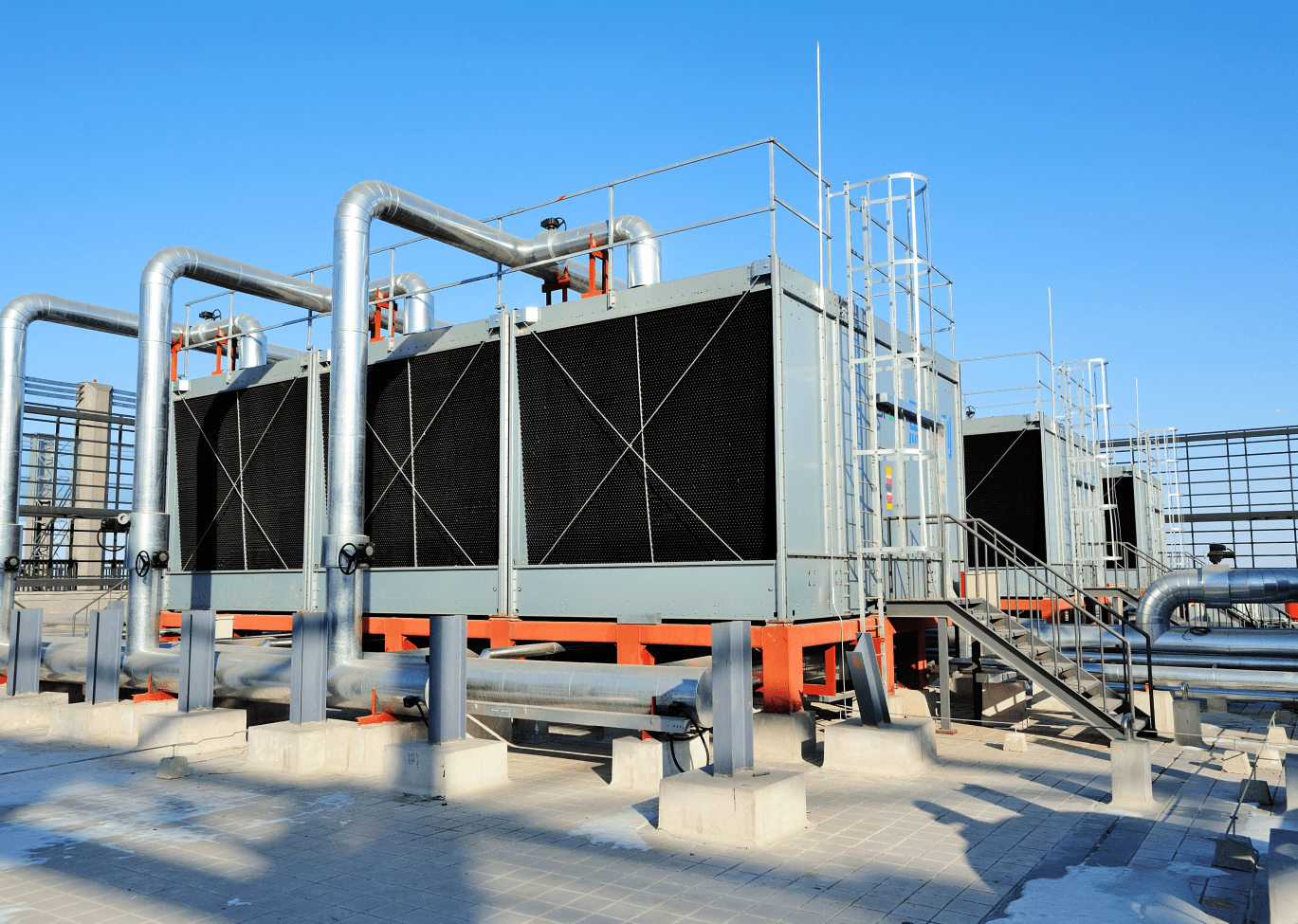

To treat your cooling tower you will need chemical feed pumps, treatment control system, filtration, and monitoring probes. Cooling towers are used to remove heat from a variety of industrial and commercial applications. However, the water used in cooling towers can become contaminated with minerals, microorganisms, and other impurities. This can lead to a number of problems, including corrosion, scale formation, algae growth, and Legionnaires’ disease.

To prevent these problems, it is necessary to have a comprehensive water treatment program in place. This program should include the use of appropriate chemicals and equipment to maintain the quality of the cooling tower water.

Types of Equipment for Cooling Tower Water Treatment

The type of equipment you need for your cooling tower water treatment program will depend on the specific needs of your system. However, some common pieces of equipment include:

- Chemical feed pumps: These pumps are used to add the appropriate chemicals to the cooling tower water in order to prevent corrosion, scale, and algae growth.

- Filtration systems: These systems are used to remove particulate matter from the cooling tower water, which can help to prevent fouling and clogging.

- Controllers: These controllers monitor the water quality in the cooling tower and automatically adjust the chemical feed rates as needed.

- Monitoring probes: These probes measure the water quality in the cooling tower and provide data that can be used to optimize the water treatment program.

In addition to these basic pieces of equipment, you may also need other specialized equipment, such as:

- Side Stream Filtration systems: These systems remove very small particles from the cooling tower water, which can help to prevent Legionnaires’ disease.

- Softener systems: These systems remove dissolved minerals from the cooling tower water, which can help to prevent scale formation.

The Importance of Choosing the Right Equipment

The specific equipment you need will depend on the size and complexity of your cooling tower system, as well as the specific water quality requirements. It is important to consult with a qualified water treatment specialist to determine the best equipment for your needs.

Here are some additional tips for choosing the right equipment for your cooling tower water treatment program:

- Make sure the equipment is compatible with the type of cooling tower you have.

- Choose equipment that is easy to use and maintain.

- Consider the cost of the equipment and the cost of the chemicals you will need to use.

- Inspect the equipment regularly to make sure it is working properly.

By following these tips, you can choose the right equipment for your cooling tower water treatment program and help to extend the life of your system.

The Benefits of Proper Cooling Tower Water Treatment

Proper cooling tower water treatment can provide a number of benefits, including:

- Prevention of corrosion: Corrosion can damage the components of a cooling tower system, leading to costly repairs or replacement. Proper water treatment can help to prevent corrosion by controlling the pH of the water and adding corrosion inhibitors.

- Prevention of scale formation: Scale can build up on the components of a cooling tower system, reducing efficiency and increasing the risk of leaks. Proper water treatment can help to prevent scale formation by adding scale inhibitors.

- Prevention of algae growth: Algae can grow in cooling tower water, leading to foul odors and the potential for Legionnaires’ disease. Proper water treatment can help to prevent algae growth by adding algaecides.

- Improved water quality: Proper water treatment can help to improve the overall water quality in a cooling tower system. This can lead to increased efficiency, reduced maintenance costs, and improved safety.

Conclusion

The right equipment for cooling tower water treatment can help to extend the life of your system and prevent a number of problems. By following the tips in this article, you can choose the right equipment for your needs and ensure that your cooling tower system is properly protected.

In addition to the equipment mentioned above, there are a number of other factors that can affect the effectiveness of your cooling tower water treatment program. These include:

- The quality of the make-up water

- The frequency of water treatment

- The amount of chemicals used

- The monitoring and maintenance of the system

It is important to regularly monitor the water quality in your cooling tower system and adjust the water treatment program as needed. By taking these steps, you can ensure that your cooling tower system is properly protected and operating at peak efficiency.